Technologies

Discover the technologies behind our solutions that drive sustainability and ensures economic viability.

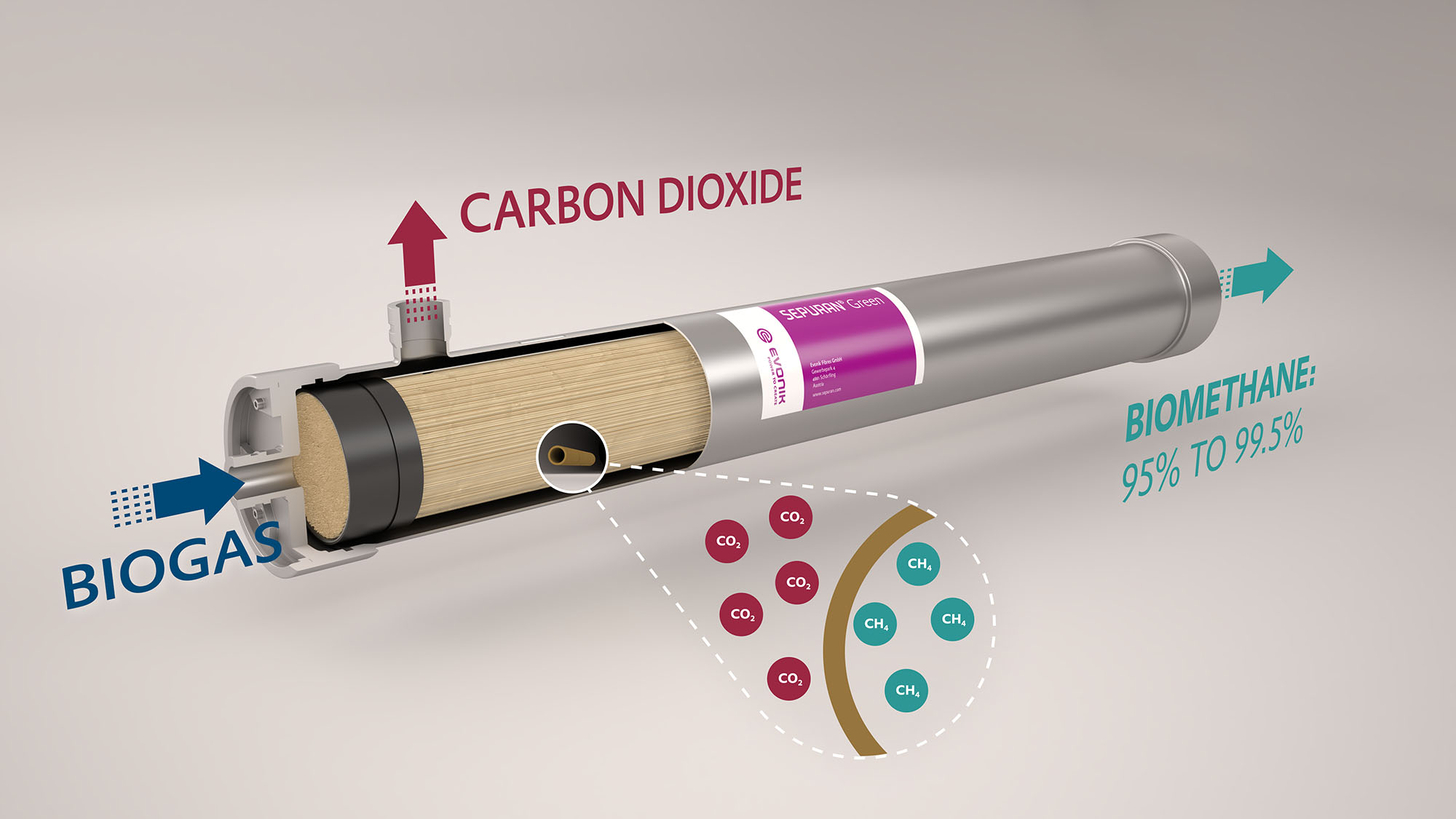

The advantage of membrane upgrading plants over conventional technologies lies, among other things, in the simplicity of the process and the low maintenance requirements. Gas separation using membrane technology takes advantage of the different molecular sizes and molecular interactions. Membrane cartridges and modules are manufactured from hollow fiber membrane bundles, which are used as membrane systems for gas separation.

In the biogas upgrading process, raw biogas is compressed and fed into the interior of the hollow fiber membrane (feed side), while CO2 is mainly directed to the outside (permeate side) due to the properties of the membrane. Methane is collected at the end of the membrane (retentate side) in a highly concentrated form. By means of multi-stage interconnection it is possible to achieve a separation of the gas mixture of nearly 100%. Methane is available with a purity of more than 95% and CO2 with a purity of more than 99%. Depending on the application, higher purities are also possible.

*Source: Evonik Industries AG

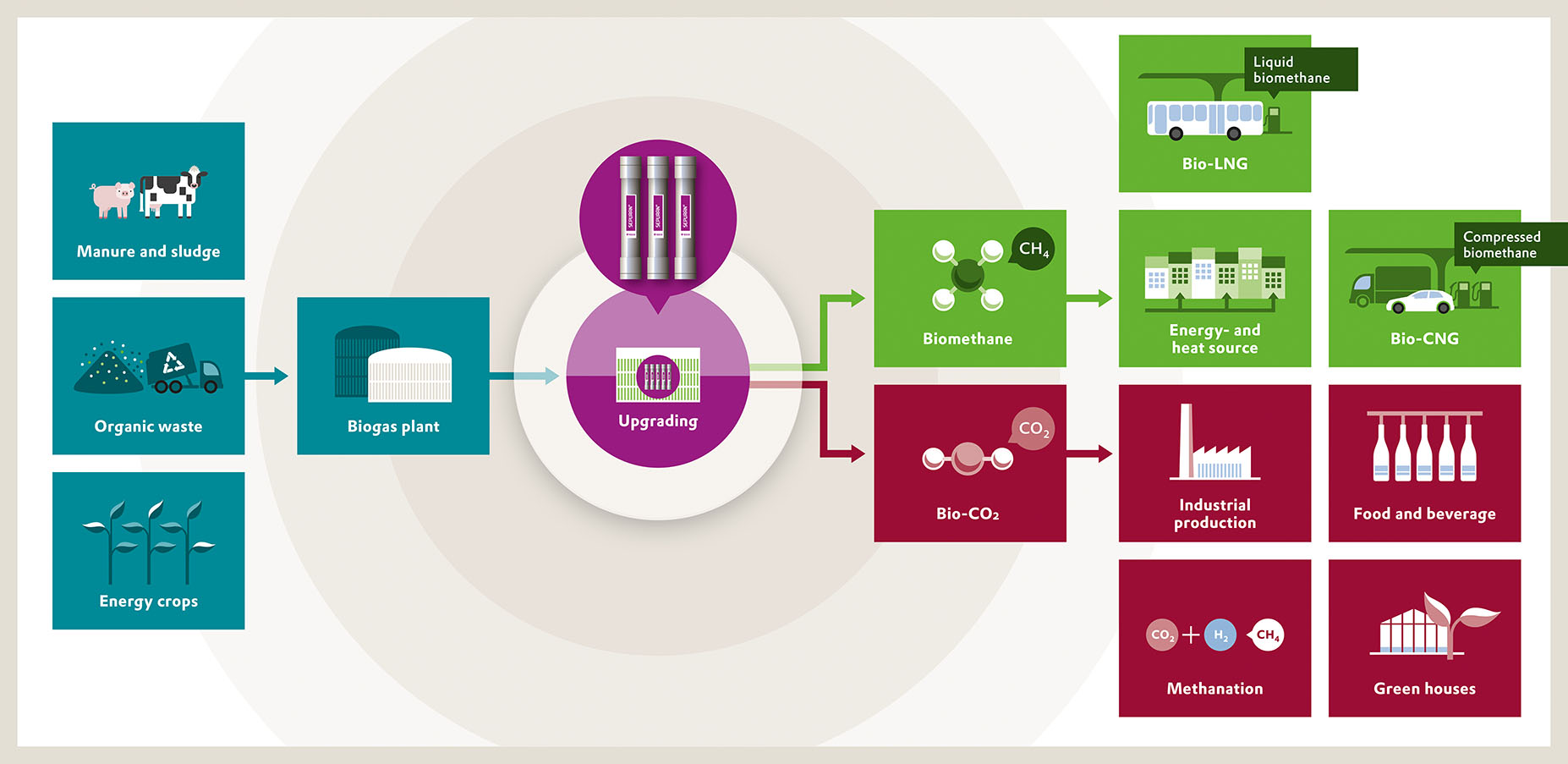

*Source: Evonik Industries AG

CO2 Recovery

In addition to the production of biomethane, CO2 that is extracted during the biogas upgrading process can be captured, recovered and liquefied with Astra Tech’s systems to produce food/industrial-grade CO2. This liquid CO2 can bring additional revenue sources and can be used in green houses, food and beverage industry, industrial production and more.

Virtual Pipeline

Biomethane gas composition reflects the same as natural gas composition. It can be delivered directly to the user through pipeline, or injected to the natural gas distribution grid available in the area. In some cases, due to the fact that the source of biomethane is located in remote areas and unfeasible to extend channels of gas delivery through direct pipeline, Astra Tech can provide alternative ways for the delivery of biomethane that is through compressed biogas (CBG), which uses the concept of a virtual pipeline.

The premise of Astra Tech’s virtual pipeline is that biomethane gas can be economically handled and transported effectively to any location where a logistic vehicle can go. The biomethane gas after being compressed, is filled into specialized tank skids called Gas Transport Modules (GTM) at an average pressure of 200 – 250 kg/m2 (bar). The tanks are then delivered using truck fleets and even through ships to desired areas. The volume of gas that can be delivered per shipment is dependent on the type of transportation mode being used. The bigger the capacities of the truck fleet, for instance, the more CBG is able to be transported.